55 Chevy Four Door "Gasser" new pg 2

The transmission blew in the '55 Chevy gasser.

This is the fourth time, so time to put in a stronger transmission.

The present Doug Nash 5 speed has the following gear ratios:

3.28, 2.13, 1.57, 1.24, 1.00

And is rated at 450 ft-lbs.

The new transmission, from Richmond Gear, has the following gear ratios:

2.89, 1.85, 1.31, 1.00, 0.77

And is rated at 600 ft-lbs.

This change in gear ratios will require a change in the rear end

differential gear ratio. The old one is 3.50:1, this will be changed to a 4.56:1,

which will match the changes in the transmission for street driving.

Here's some data to compare the old with the new:

Present road speeds in each gear at 2,500 rpm:

18, 28, 38, 48, 59 mph

With the new setup, I'll get these speeds:

16, 25, 35, 45, 59 mph

If I were to run the 4.11 rear end I'd get these speeds:

17, 27, 38, 50, 65 mph

So that's an option also....

More later....

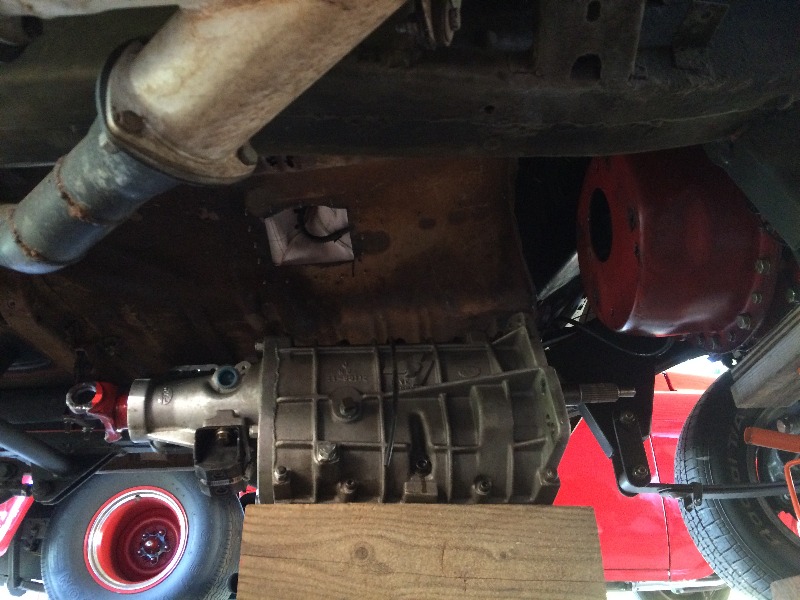

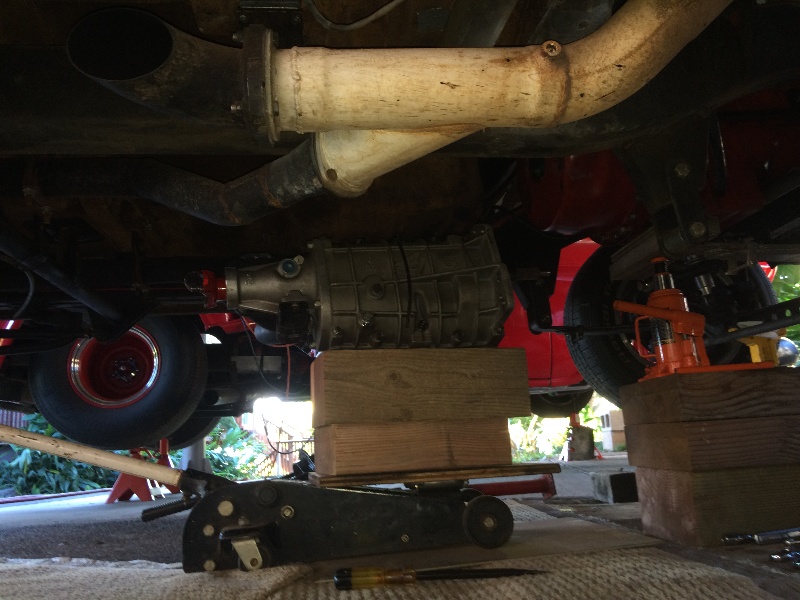

OK, finally gut my butt under the car and unbolted everything...

Had to put a couple of blocks on my tranny plate on my floor jack

to reach the tranny, I had the car jacked up pretty high, easy to get under...

My damaged left hand, got it workin' pretty well, unscrewing bolts....

Balancing that 30+ year old Doug Nash five speed on the blocks...

(That's the '58 pro street truck next door)

Good shot of the blow bell

Had the car up too high, had to block up the tranny plate on my jack

(the 58 truck next door needs a brake job...)

Got 'er out, now to find out what I broke.....

This time !!!

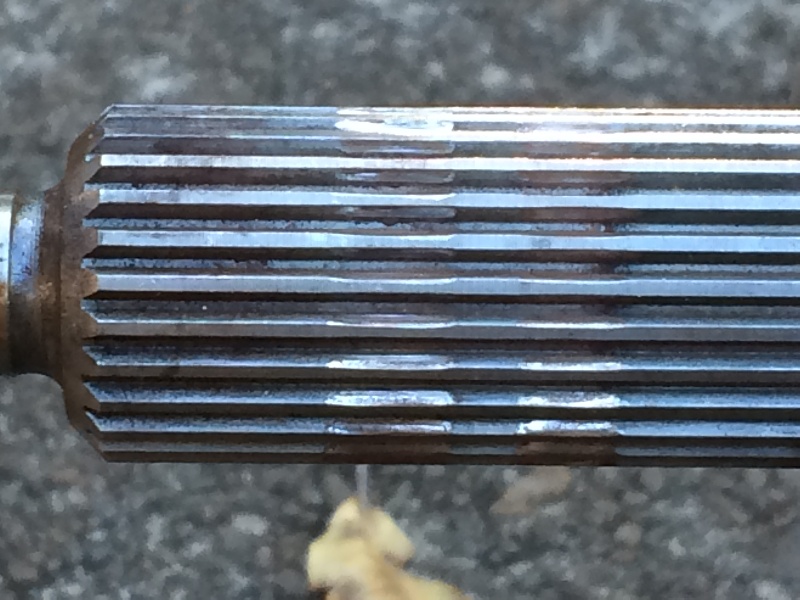

OK, got it up on the bench, first thing I noticed is that the splines on the input shaft

are showing a fair amount of wear, this is a new shaft I just put in less than a year ago...

It's a dual clutch plate setup, you can see the separate set of wear marks

from each clutch plate....

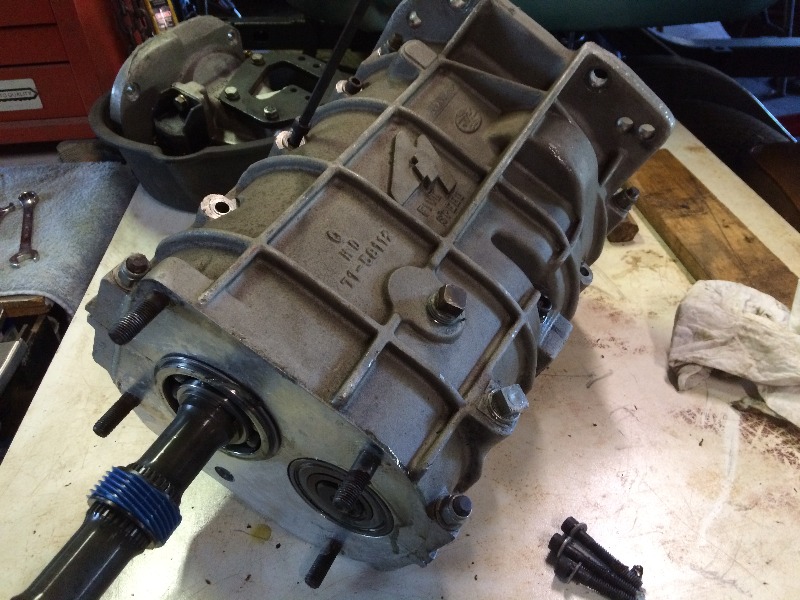

Pulled the rear output shaft case off....

Pulled the front release bearing guide off...

Removed the case half bolts, ten of them...

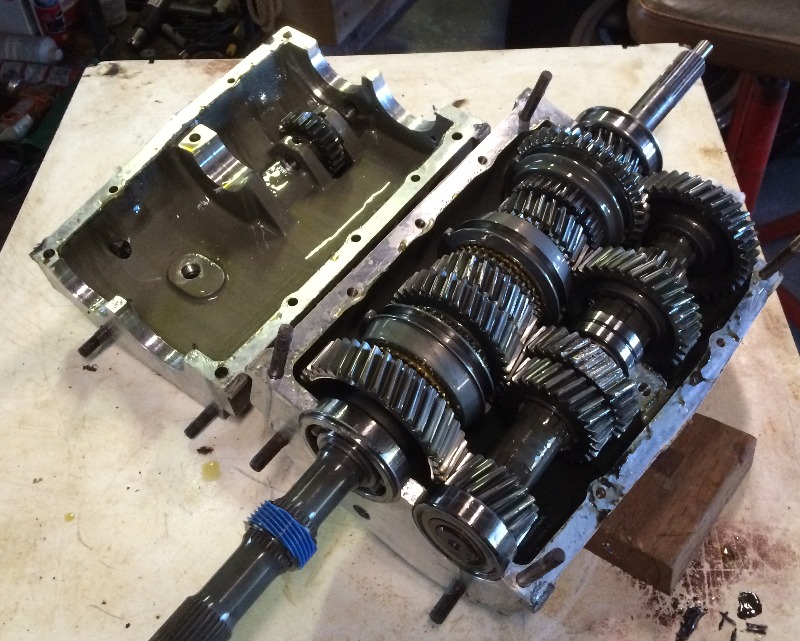

Popped the right side case half off....

And saw that about five teeth were missing from the counter shaft 3rd gear...

The mainshaft 3rd gear is not too bad, some damage, but it would be reusable,

and it would be noisy, however I always replace these in pairs, if I can get them....

Here's the same shot, but with a flash, not much difference...

A closeup...

Not as clear as I would like, but you get the idea...

I've been calling around looking for a set of 3rd gears for this box,

I can get the mainshaft gear, but have not been able to locate a

counter shaft (or cluster shaft if you prefer) gear...

Frustrating!!

Below I popped both shafts out of the box, the main shaft bearings all spin

cleanly and quietly, I do not think any of the debris from the busted teeth on the

counter shaft third gear got into the bearings. I'm going to take a chance on this

and just clean up everything on the main shaft pretty thoroughly without disassembly

and only work on the counter shaft.

I have three magnets epoxied in the bottom of the gear box, they picked up the metal trash...

Close ups of those magnets

I popped the magnets out, they jumped together and I can't get them apart...

I'll put fresh magnets in when I reassemble the gearbox...

Pulled the 1st, 2nd and 3rd gears off, unfortunately 2nd and 3rd share a common spline

so I'm going to have to fab a spacer to hold 2nd gear in position...

A piece of 2" pipe will work, need to cut it exactly the same width as 3rd gear...

More Later...

Some Discussion

The real problem with the Richmond Gear design, as I see it, is that the main shaft and the input shaft,

which fit together as a single inline unit, have no intermediate support anywhere,

it is only supported on the ends, making it weak where the input shaft fits into the main shaft.

This allows it to flex under heavy loads, spreading the gear sets apart so that there is less

than full face contact between the gears. Under heavy loads this eventually causes the gears

to give way at the tips, or the outer half of the gear tooth, then it all goes away from there...

Look at the fuzzy close up pic of the failed 3rd counter shaft gear above,

a good part of the gear tooth root is still there. Once the loose parts were cleared away,

the 3rd gear set still meshes and turns, as there is still enough of the gear tooth root

left to mesh with the teeth on the main shaft gear.

I've been told that GForce and Liberty both support the mainshaft in the middle

somehow to prevent this deflection, making a stronger gear box. Am checking that out.

I've been looking at a Jerico, they have many gear options in their road race 5 speed.

I don't know yet if they also have additional support on their main shaft setup.

I also just don't know how I can afford that box.

As I like a wide ratio spread for out on the road, I've been playing with

Jerico's gear ratio selections and have come up with this as a possibility:

This is the Jerico Gear Ratios I've selected,

shown with % change to the next gear:

1st, 3.58, 36%

2nd, 2.29, 27%

3rd, 1.68, 24%

4th, 1.28, 22%

5th, 1.00

For comparison, here's my current Doug Nash (also old RG) setup:

1st, 3.28, 35%

2nd, 2.13, 26%

3rd, 1.57, 21%

4th, 1.24, 19%

5th, 1.00

One more comparison, the new OD Richmond Gear 5 speed:

1st, 2.89, 36%

2nd, 1.85, 29%

3rd, 1.31, 24%

4th, 1.00, 23%

5th, 0.77

Richmond Gear has run the ratio range up from the earlier 3.28 to 1.00,

to the present "overdrive" 2.89 to 0.77.

By changing my rear end gearing from a 3.50 to either a 4.33 or a 4.56,

I'd barely notice the difference between the earlier gear ratio set and the

new gear ratio set for the Richmond Gear setups.

They moved those ratios up to decrease the gear tooth stress inside the box.

This allows them to up the power rating from 450 ftlbs to 600 ftlbs.

But really, their gear box is still just as weak without any middle support on that main shaft.

With my 31" tall tires, and a 3.50 rear gear, I get the following road speeds

at 2,500 rpm with the Jerico gears shown above:

1st, 18 mph

2nd, 27 mph

3rd, 33 mph

4th, 42 mph

5th, 66 mph

Taking each gear to 3,500 to shift I get:

1st, 26 mph

2nd, 38 mph

3rd, 47 mph

4th, 59 mph

5th, 92 mph, oops!

I redline this motor at 5,500:

1st, 40 mph

2nd, 60 mph

3rd, 74 mph

4th, 93 mph

5th, 145 mph

Nawww, that'll never happen!

Always fun to work through these calcs and imagine "what if...."

To the new Page 3

To the new Page 4

To the new Page 5

Back To the new Page 1

To the Old Pages

To the '55 gasser home page