55 HT project page 32

Needed to take some measurements of this clutch release bearing fork and

the Tee stand it levers the release bearing off of....

There's a fair amount of "slop" where the fork fits on the release bearing coller inside....

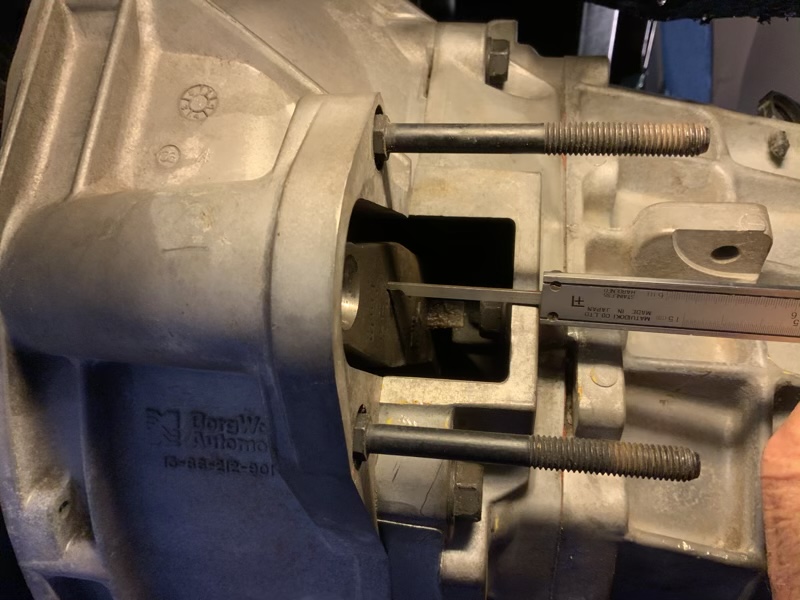

Took a measurement on the fork at this point,

as there was a convenient place to measure from....

Then decided I better mark that spot on the fork....

A better spot on the fork is here, but more difficult reference location...

Clamped it down, releasing the pressure plate a bit,

until the fork was up against the pressure plate housing....

And managed to get a measurement....

Pulled the tranny and started taking measurements....

Getting faster, only took 30 minutes to get it out of the car this time...

Probably getting more measurements than I really need....

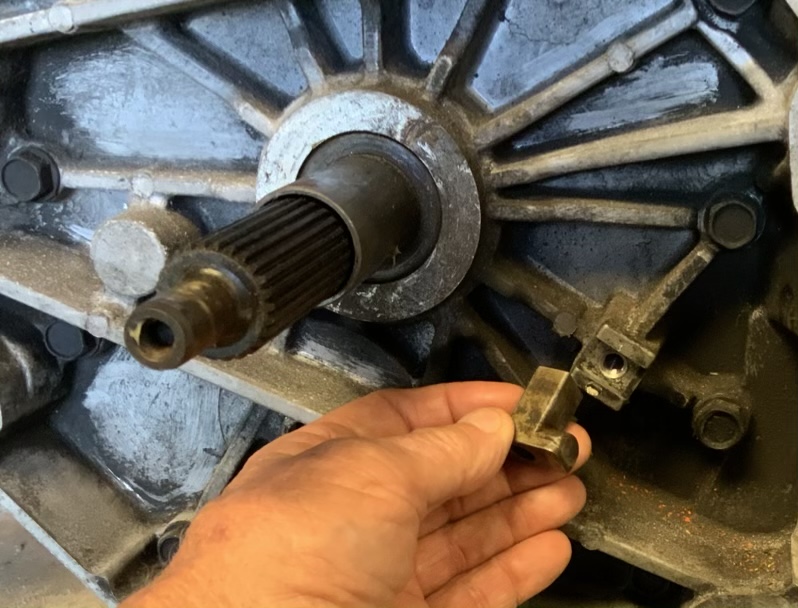

But by milling off some of the bottom of this "Tee Stud" that the fork arm

rides on, I can move the fork back away from the pressure plate...

I went online and found a spare "tee stud", so now I have

a backup on the way just in case I mess this one up....

This tee post is only 1-1/16" tall, there's not a lot to trim here....

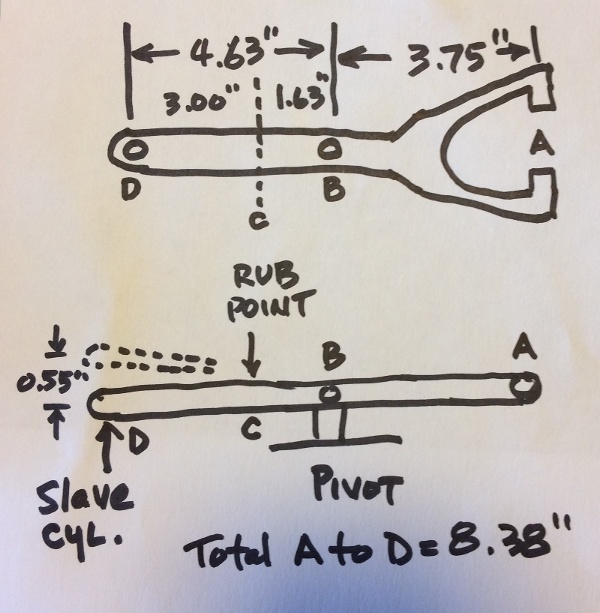

Drew this up to help visualize the problem and what might be done to solve it...

Marked the fork end "A", the pivot "B", the rubbing point "C", and the slave cylinder at "D".

The ratio of 1.63" / 4.63" = 0.35, which means the closer to point B you get, the less the fork

moves toward the pressure plate housing, so 0.35 times the movement at point "D", 0.55"

gives a movement of 0.19" to contact at point "C", that is, the clearance at point "C" is only 0.19"

when the fork is not doing it's job.

Shortening the Tee stud to gain more clearance at point "C" is quite doable, but how much??

My slave cylinder at point "D" is capable of 1" of movement, plus I want clearance at point "C"

if point "D" is at full movement of 1". So, first let's see how much movement there will be at

point "C" if I can move point "D" a full one inch....

Using ratios, 1" of movement at 4.63" from "B" to find "x" at 1.63" from "B", or:

1/4.63 = x/1.63, or:

x=1.63(1/4.63) = 0.35"

Now to calc how much to shorten the Tee post at point "B", we need to consider the fork as

fixed at the release bearing, point "A", and calc ratios from there...

Since point "D" now has 0.55" movement before it hits, let's calc the additional it needs before it hits

for a full 1" of movement: 1" - 0.55" = 0.45" additional movement is needed,

figuring from point "A", 0.45"/8.38" = x/3.75", or:

x=3.75(0.45/8.38) = 0.20"

So if I shortened the Tee post by 0.20" I would have a full inch of movement

at point "D" where the fork would then hit the pressure plate.

Ok, if I shortened the Tee post at "B" to give 1.5" movement at "D", how much

would I have to shorten it??

First the additional movement needed at "D", 1.50" - 0.55" = 0.95"

Again, ratios: 0.95/8.38 = x/3.75

x = 3.75 (0.95/8.38) = 0.43"

That's a lot to take off of that Tee post !

It's only 1.06" tall, removing 0.43" leaves 0.63", not much!

1.5" movement at "D" will give how much movement at "C" to contact the pressue plate?

1.5"/4.63" = x/1.63"

x=1.63(1.5/4.63) = 0.53" at "C" to contact the pressure plate.

If the clearance at "C" is going to be zero with the shortened post at "B" and full 1.5" movement

at "D", what is the clearance at "C" with only 1" movement at "D" ??

0.5"/1.5" = x/0.53"

x = 0.53(0.5/1.5) = 0.18" clearance at point "C"

I do need to take a serious look at what other effects might come up if I shorten that Tee post 0.43" !!

Took another look at the Tee Post mount, the fork, and the release bearing...

There is only 0.512" protruding out of the fork...

And those side rails on the mounting stand are 0.191" high,

that leaves 0.321" available to cut, but I also need to allow room

for the fork to rocker back and forth, how much do you suppose that is?

I tried to measure it, came up with about 0.025",

so that leaves only 0.296" max that can be cut !!

Had another thought though, let's check where the release bearing

sits on the tranny snout, I can measure that...

It turns out that the rear of the release bearing collar is

exactly flush with the rear edges of the bell housing...

That means that the rear of the release bearing is also flush with the front

edge of the tranny, so with a straight edge I was able to measure just how

much travel the release bearing had available, turns out is is exactly 1/2" !!

Using the same ratios that I used above, 0.55" movement at point "D"

gives 0.44" at point "A" (the release bearing), but we

want 0.50" movement at the release bearing (point "A")

which requires 0.62" of travel at the slave cylinder (point "D")

Since I already have 0.55" travel available at point "D", I just need to

add 0.07" to get 0.62" movement at "D", getting 0.50" at the release bearing.

In order to get this, I only need to trim the tee post by 0.030"

But I'd be touching the pressure plate housing, so I need to add

additional clearance for the pressure plate...

I ran the numbers several times, and came up with these results:

Trim the tee post 0.080" gives 0.070" clearance,

Trim the tee post 0.100" gives 0.100" clearance,

Trim the tee post 0.150" gives 0.170" clearance,

It looks like all of these trim options will not cause other problems,

taking into account the angular movement of the fork on the tee post,

the amount of post exposed under the fork, and the amount of the tee post

required to fit into that base mount on the tranny, I have about 0.296"

available for a maximum trim job before I might run into a functional interference.

So, the real question is, just how much clearance do I really

need for the pressure plate housing ??

My feeling at this point is to trim the tee post 0.100" and see if I can live

with 0.100" clearance at the pressure plate housing...

The real problem is that I do not know just how much movement that clutch

needs to function properly, am searching for that number....

I'm pretty sure 0.500" is way over what's needed....

Trimmed the tee post by 0.153”, let’s see how that fits....

With the shortened tee post, I had to shorten the mounting bolt an equal amount, it was too long...

But the tee post and fork went back together nicely on the front of the tranny, no problems...

Put the tranny back in the car, the fork "popped" back into position nicely on the release bearing,

and I was able to get a measurement at this end of that fork...

Was able to get a pic, difficult to do under there...

This photo is misleading, the end of the fork actually now sits slightly above the surrounding metal...

This pic shows the full movement of the clutch release bearing on the other end,

I measured 0.800" total movement at this end, and was able to determine

that there was plenty of clearance at the pressure plate housing....

I bent a heavy piece of wire and hooked it up in there under the fork, between the fork and

the pressure plate, and felt around a bit, when the fork was fully depressed, felt like plenty of clearance...

I still need to cut an inspection hole in the clutch cover, haven't made up my mind yet where and how big to make it....

More Later