55 HT project page 33

Back to the '55 Hardtop Home Page

Still messin' with that clutch setup....

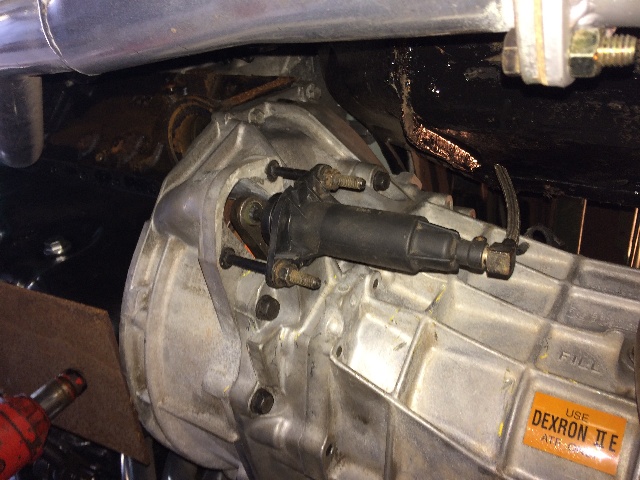

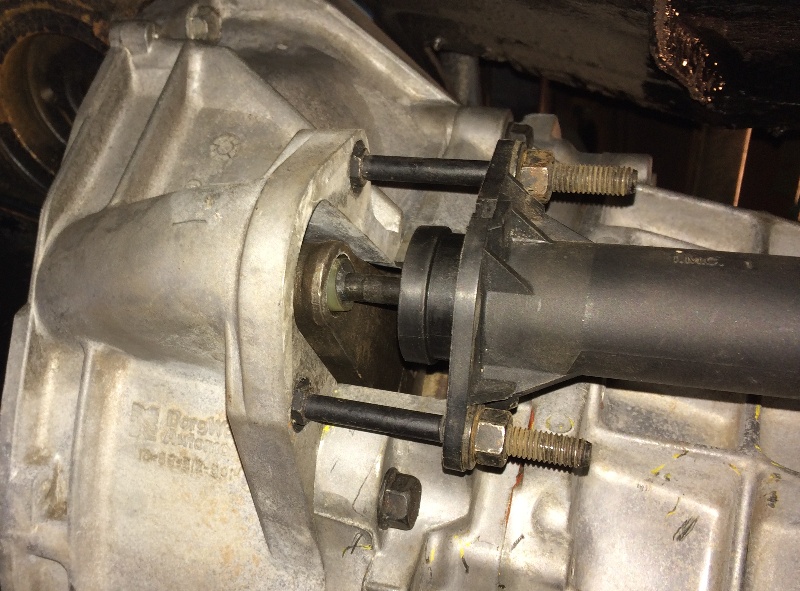

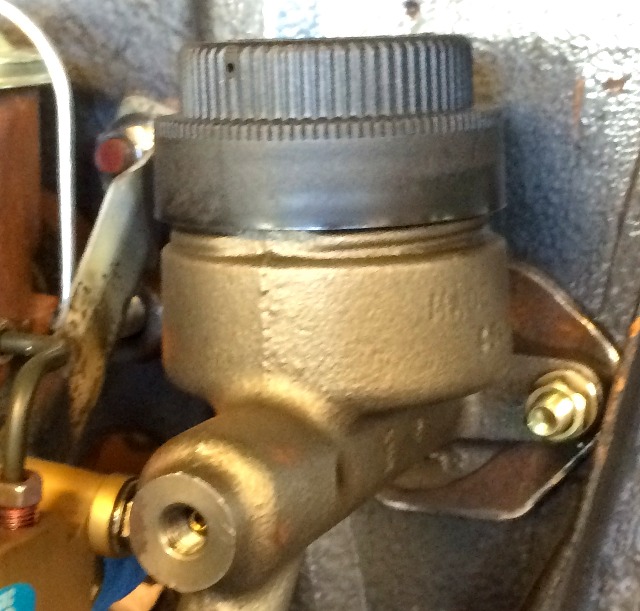

Removed the support piece that goes between the slave cylinder

and the clutch housing, and mounted the slave cylinder

with the piston completely compressed inside the cylinder...

Measured this distance between the clutch housing and the cylinder, 1.643"...

Reassembled it with the support piece, which is 2.000" wide,

which gives me 0.357" of piston travel behind the

open cylinder still available behind the piston...

With a total stroke in the slave cylinder of 1.5",

and a max clutch fork movement of 0.80"

(probably less) I should be good to go with this setup!

Put it all back together...

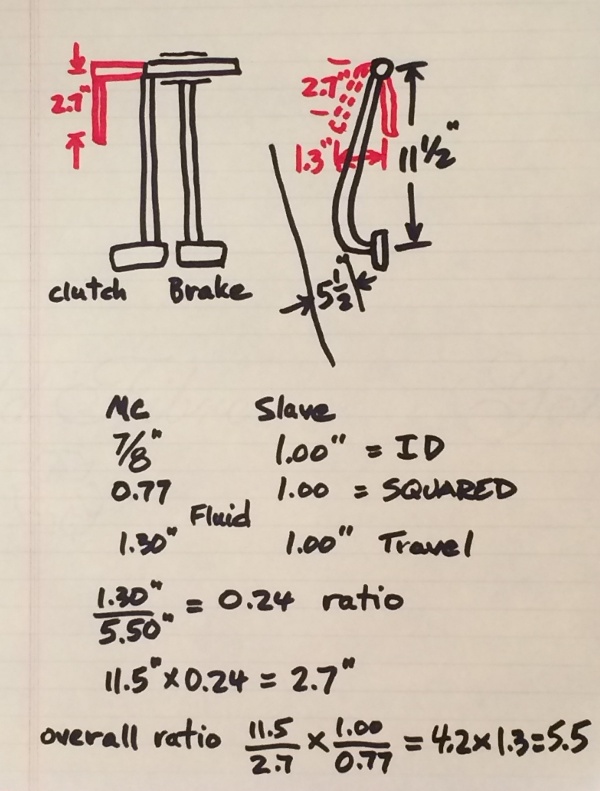

Now to look at the clutch pedal and linkage....

The chalk mark by that lower bolt is 2.7" down from the pivot...

Which is where I think I want to put the clutch

master cylinder push rod...

This gives me the max. amount of leverage that I want to try for,

but should give me lots of foot pedal travel and a fairly light

pedal effort. If I move the attachment point further down, it

will increase foot pedal effort but give me a faster action at the pedal.

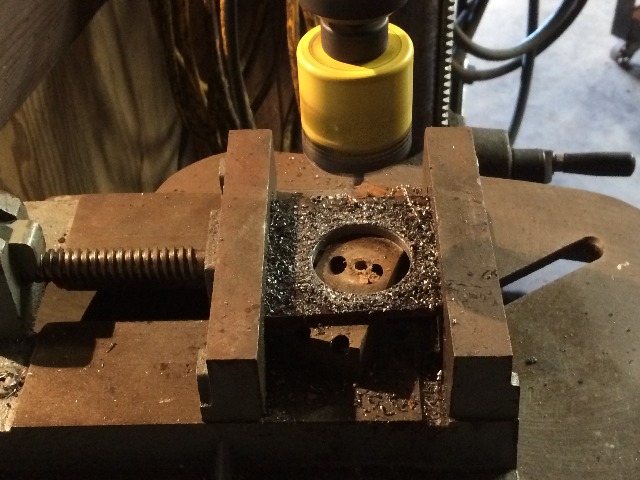

Got the hole saw out and started marking off measurements....

Drilled that hole first from the front side.

Had to pull off the brake MC to get access with the drill for the bolt holes...

Tried to get at the passenger side hole with the drill from underneath,

No Way, so off came the brake MC....

That "ridge" on the left side of the MC (viewed from the front) needed

to be flattened with a hammer, or a spacer needs to be fabbed....

So made a pattern...

Had that piece of 1/4" in the scrap pile, so used that...

The pattern looks good to go....

Gotta cut off the left side where the firewall ridge hits it...

Cut the big hole first....

Go from there....

Looks good on the MC...

Looks good on the firewall...

Fabbed another 1/4" plate for the inside, with the 3/8" bolts

welded on to stuff through and bolt up from the front side....

Now it needs some paint

Everything bolted up quite nicely....

My spacer worked perfectly....

The inside plate with bolts also seems good to go....

Now to take it all apart and paint the parts.

Gave in and bought this bore scope at my local Home Depot...

Finally located a clevis the right size to attach to a 3/8" rod and the clutch pedal...

Ran down about 3" of thread so I'll have lots of adjustment available...

Looks good to me, will add another hex nut weded to the rod below the thread for a wrench...

Cut and welded an offset from 1/4" scrap to set the "push" point 2-3/4" down

from the pedal pivot, and 2-1/4" over to the left to center on the clutch MC...

Now I need to cut the rod to the correct length and round off the end to match the MC piston...

More Later....